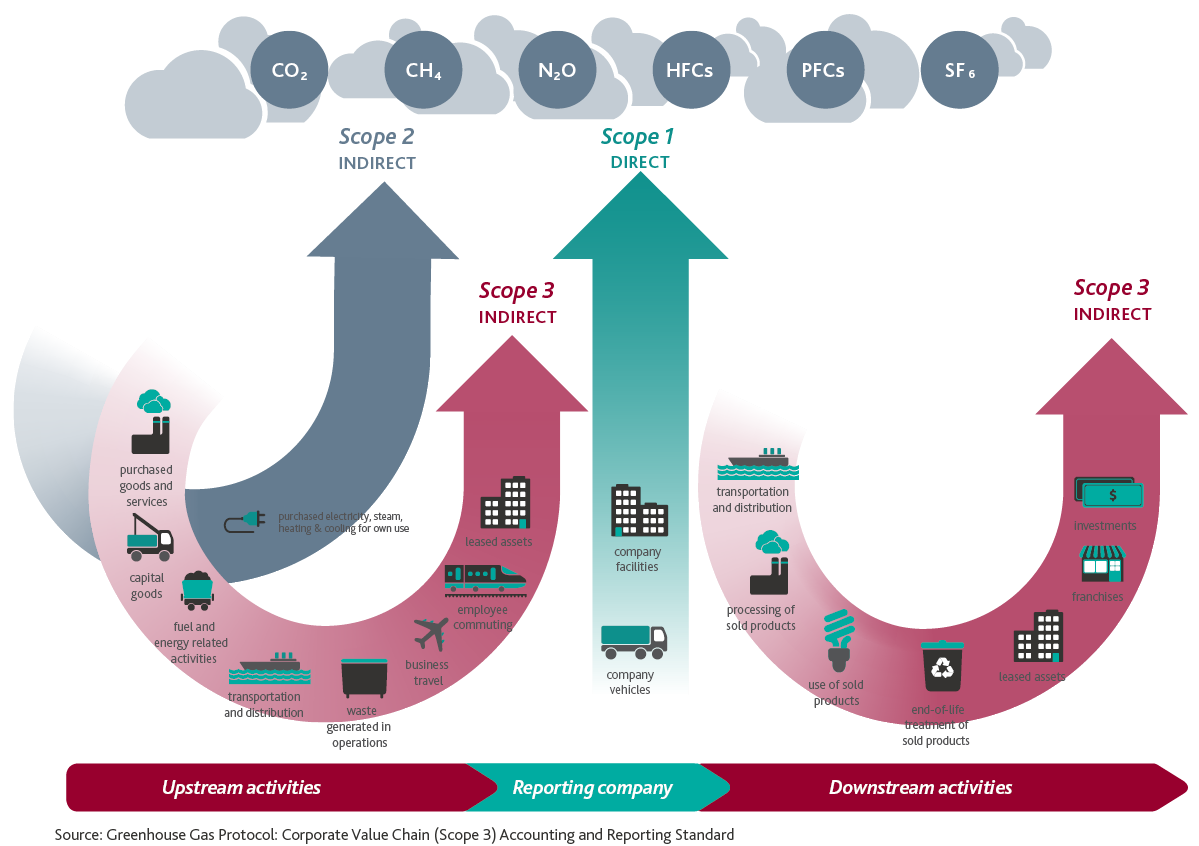

Scope 1, 2, and 3 emissions are fundamental in the sustainability efforts of businesses, particularly in the food manufacturing industry. These categories are pivotal for effective carbon accounting and reduction strategies. This article aims to clarify Scope 1, 2, and 3 emissions, using a cookie manufacturer as a case study.

(This article was previously posted on LinkedIn by Hans de Gier.)

Understanding Scope 1 Emissions

Scope 1 emissions represent direct emissions from sources owned or controlled by the company. For a cookie manufacturer, these include emissions from gas ovens and company-owned vehicles.

Understanding Scope 2 Emissions

Scope 2 emissions refer to the emissions that come from the electricity, steam, heating, and cooling that a company buys and uses. Consider a bakery brand that switches from gas to electric ovens. The emissions from gas ovens were Scope 1 emissions, but when they switch to electric, the emissions associated with electricity generation for these ovens fall under Scope 2. If this electricity is sourced from renewables like wind or solar power, Scope 2 emissions can be significantly reduced.

Decoding Scope 3 Emissions

Scope 3 emissions encompass all other indirect emissions in the company’s upstream and downstream value chain.

Upstream Emissions

These are emissions from producing raw materials (flour, eggs, butter, salt) and packaging materials used in cookie manufacturing. So emissions related to all materials and services you source (except energy!).

Downstream Emissions

In addition to upstream emissions, a company’s environmental impact is significantly influenced by downstream emissions in your value chain. These emissions occur during and after our products reach the market and include the following key areas:

- Retailer Operations and Point of Sale Emissions: This category includes: Freezer Storage Emissions: For products like deep-freeze chocolate lava cakes, the energy used by retailers for freezer storage contributes to their Scope 1 and 2 emissions. For the cookie manufacturer, these are Scope 3 emissions.

- In-Store Baking Emissions: Emissions from baking products like chocolate chip cookies in-store are the retailer’s Scope 1 or 2 emissions, depending on the energy source. But for the bake-off products brand manufacturer, these are categorized under Scope 3.

- Consumer Usage Emissions: Emissions from consumers storing and preparing the products, including home freezing and baking. End-of-Life Emissions: Emissions associated with the disposal or recycling of packaging.

Integrating Transportation Emissions into Scope 3

An important aspect of Scope 3 upstream emissions for the cookie manufacturer, in our example, involves the transportation of raw materials like eggs and plastic foil to their factory. This transportation element is crucial in the context of the broader Life Cycle Assessment (LCA) definitions and sustainability data exchange across the value network, as discussed in the previous post “Do We Need LCAterms to Enable Sustainability Data Exchange Across the Value Network?”

Transport Emissions from Suppliers: The emissions from vehicles (not owned by the manufacturer) transporting raw materials to the factory are classified under Scope 3 upstream emissions. This includes emissions from the logistics involved in delivering eggs, flour, butter, salt, and packaging materials to the manufacturing site.

Own-Vehicle Transport Emissions: In cases where the manufacturer uses its own trucks to pick up materials from a supplier’s distribution center, these emissions are categorized under Scope 1, as they are direct emissions from vehicles owned or controlled by the manufacturer.

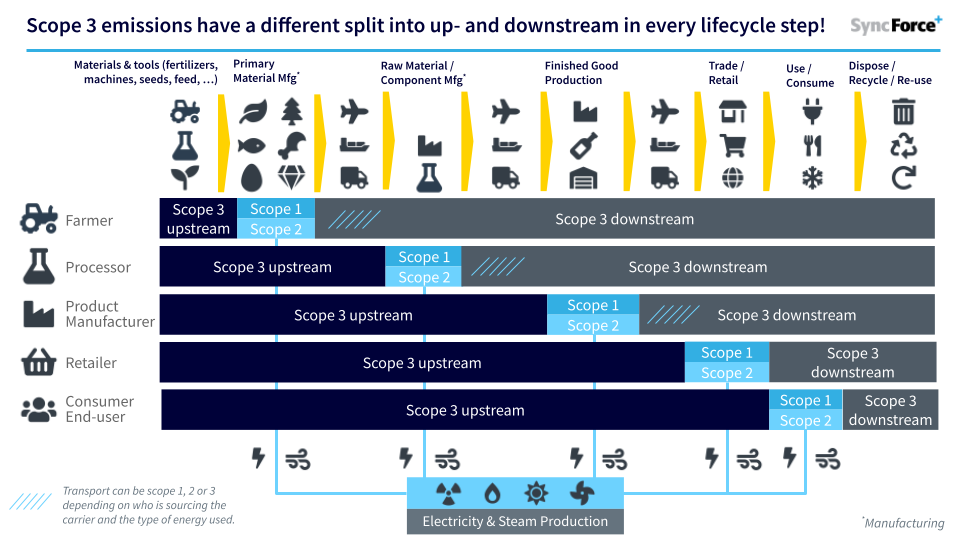

The figure below shows that Scope 1,2,3 emissions are not absolute values but depend on the perspective of the reporting party.

Conclusion

Understanding the nuances of transportation emissions in the context of Scope 1 and Scope 3 is essential for food manufacturers and other businesses in the food industry. It underscores the importance of considering every element in the supply chain, from sourcing raw materials to recycling, in carbon accounting and sustainability strategies. This approach is integral to achieving a comprehensive understanding of a product’s environmental impact, in line with LCA principles and effective sustainability data exchange.

It’s important to note that “Scope 3 emissions for this product” can mean different things depending on where in the lifecycle the value is determined. The Scope 3 emissions value is not a static figure but rather a dynamic one that changes as the product moves from production to disposal. Retailers often refer to the GHG emissions value (in kgCO2eq) delivered at their doorstep, which doesn’t account for downstream Scope 3 emissions such as consumer use or end-of-life disposal. Therefore, when discussing Scope 3 emissions, specificity is key. We cannot talk about a singular “Scope 3 value” without context. As shown in the visual above, a comprehensive view of a product’s emissions requires considering every stage of its lifecycle, highlighting the need for a shared understanding and consistent data exchange mechanisms across the value network to enable holistic sustainability assessments and strategies.